When it comes to safeguarding your business or property from unexpected power outages, few investments are as vital as a high-quality generator. But simply purchasing a generator isn’t enough. To ensure that your backup power system is always ready to spring into action, regular generator maintenance is absolutely essential.

At National Generator Sales, we’ve been at the forefront of power generation for over 45 years. We supply cutting-edge generators tailored to the needs of homes, businesses, and critical infrastructure alike. Strategically located just 36 miles from London and 15 miles from Cambridge, we’re perfectly positioned to serve clients across a wide range of industries throughout the U.K.

Although we do not offer generator maintenance services ourselves, we strongly advocate for the upkeep of your system through a trusted and qualified maintenance provider. In this blog post, we’ll explain why regular generator maintenance is crucial, the signs your generator may need attention, and what’s typically included in a standard maintenance plan. Let’s get started…

The Importance of Regular Generator Maintenance

Generators often lie dormant for long periods. Then, in an emergency, they’re expected to perform instantly and flawlessly. The truth is, neglecting maintenance can lead to failure when you need your generator most, risking downtime, damage to equipment, and even health and safety issues. The assumption that your generator will “just work” can result in complacency, which is a risk no business should take. Even minor component issues, such as a clogged filter or a corroded battery terminal, can prevent startup or impair performance. Consistent maintenance is the proactive step that keeps your backup power reliable and ready to act at a moment’s notice.

Let’s take a closer look at why maintenance is non-negotiable:

Reliability in an Emergency

Regular servicing ensures your generator will work when needed. Maintenance involves checking all critical components – battery, fuel system, filters, oil levels, and electrical connections. A neglected part can cause a cascade of failures when the power cuts off. When an outage hits, every second counts, and the last thing you need is a generator that fails to respond. Reliability isn’t just about turning on — it’s about running efficiently, safely, and for as long as necessary. Maintenance ensures each part of your generator functions harmoniously to deliver consistent, uninterrupted power when it matters most.

Prevention of Expensive Repairs

Minor issues can quickly become major problems if left unchecked. Routine maintenance helps identify and fix problems early, saving you from more costly repairs or even full generator replacement down the line. Replacing a damaged alternator or engine component is significantly more expensive than addressing a loose bolt or a dirty filter. Early detection is key to keeping repair costs manageable and predictable. A proactive maintenance approach not only minimises downtime but also protects your investment in the long term.

Extended Equipment Lifespan

Like a car, a well-maintained generator will last significantly longer than one that’s not. Regular oil changes, filter replacements, and thorough inspections reduce wear and tear on the engine and other mechanical parts. With proper servicing, many generators can exceed their projected lifespan, saving you the cost of premature replacement. Longevity also ensures you maximise your return on investment over time. Simply put, maintaining your generator today helps avoid the cost of buying a new one tomorrow.

Optimised Fuel Efficiency

Dirty filters, old oil, or clogged injectors can reduce your generator’s efficiency, costing you more in fuel over time. Routine maintenance ensures your system is running as efficiently as possible, saving you money. Proper calibration and cleaning of fuel systems can improve performance and reduce wastage. In larger commercial generators, improved fuel economy can translate into thousands of pounds in annual savings. Maintaining efficiency isn’t just good for your wallet — it’s also better for the environment.

Health & Safety Assurance

Generators, particularly diesel models, emit fumes and produce heat. Faulty exhaust systems, leaks, or wiring issues can pose a serious health and safety risk. Maintenance checks help detect such hazards before they escalate. Issues like carbon monoxide leaks or electrical shorts are not just inconvenient — they can be life-threatening. Regular servicing includes checks for safe ventilation, wiring integrity, and proper exhaust operation. These inspections protect not only the equipment but also the people working nearby.

Compliance With Insurance & Regulations

For commercial operations, many insurers and regulatory bodies require evidence of regular generator maintenance. Failing to service your equipment can result in non-compliance and void insurance policies. Compliance isn’t optional when public safety, legal accountability, and business continuity are on the line. Maintenance logs and service reports provide proof of due diligence should an issue ever arise. Ensuring your generator is up to standard helps you stay protected both operationally and legally.

Peace of Mind

Simply put, knowing your generator has been properly looked after gives you confidence that it will perform under pressure. That peace of mind is invaluable, especially in critical sectors such as healthcare, data centres, and manufacturing. You’ll be free from the stress of last-minute failures, unsure performance, or unreliable emergency support. With scheduled maintenance, you can plan confidently around your generator’s availability and capacity. It’s one less thing to worry about in an already complex operational landscape.

Protects Connected Systems

Your generator doesn’t operate in isolation. A malfunctioning generator can send power surges to your systems, damaging connected equipment. Regular inspections ensure stable, clean power output. Voltage irregularities or phase imbalances can affect sensitive electronics, leading to data loss or equipment failure. Properly maintained generators provide steady voltage regulation and clean energy that protects your entire electrical infrastructure. By protecting the devices your business depends on, generator maintenance becomes a broader shield for your entire operation.

Power outages are unpredictable, but your response doesn’t have to be. The best way to ensure operational continuity is to maintain your generator like the critical asset it is. In industries where downtime equals loss, your generator is your frontline defence — and it must be ready without hesitation. Neglecting maintenance is essentially leaving your backup plan up to chance. Stay ahead by investing in consistent, professional maintenance that guarantees your peace of mind and the resilience of your business.

Signs Your Generator Needs Maintenance

While scheduled servicing is the best way to avoid breakdowns, there are often telltale signs that your generator is crying out for attention. If you notice any of the following issues, it’s time to call in a professional:

Difficulty Starting

If your generator struggles to start or cranks more slowly than usual, there could be an issue with the battery, fuel, or starter motor.

Unusual Noises

Knocking, sputtering, or grinding noises during operation aren’t normal. These could indicate internal wear, fuel injection issues, or loose components.

Excessive Smoke

White, blue, or black smoke from the exhaust points to engine troubles such as coolant leaks, oil burning, or fuel problems.

Visible Leaks

Any oil, coolant, or fuel leaks are serious and need immediate attention to prevent safety hazards or system damage.

Dashboard Warning Lights

Modern generators have diagnostic systems. Pay attention to any warning indicators on the control panel.

Inconsistent Power Output

If lights flicker or connected equipment resets during use, your generator may not be delivering stable voltage.

Overheating

Overheating could result from coolant issues, blocked vents, or excessive load. Address it before lasting damage occurs.

Higher Fuel Consumption

A noticeable drop in fuel efficiency often signals that maintenance is overdue, especially if filters or injectors are clogged.

Spotting these signs early can help prevent complete breakdowns and reduce the risk of generator failure during critical moments.

What’s included in generator maintenance?

So, what does generator maintenance actually involve? While specifics may vary depending on the make and model, as well as usage frequency, a typical maintenance checklist includes:

1. Visual Inspection

A comprehensive visual check helps spot leaks, corrosion, worn belts, or loose connections. It’s the first step in identifying issues before they become problems.

2. Oil and Filter Change

Just like a car, your generator needs fresh oil and clean filters to run smoothly. This task is usually performed every 100–200 hours of use or annually.

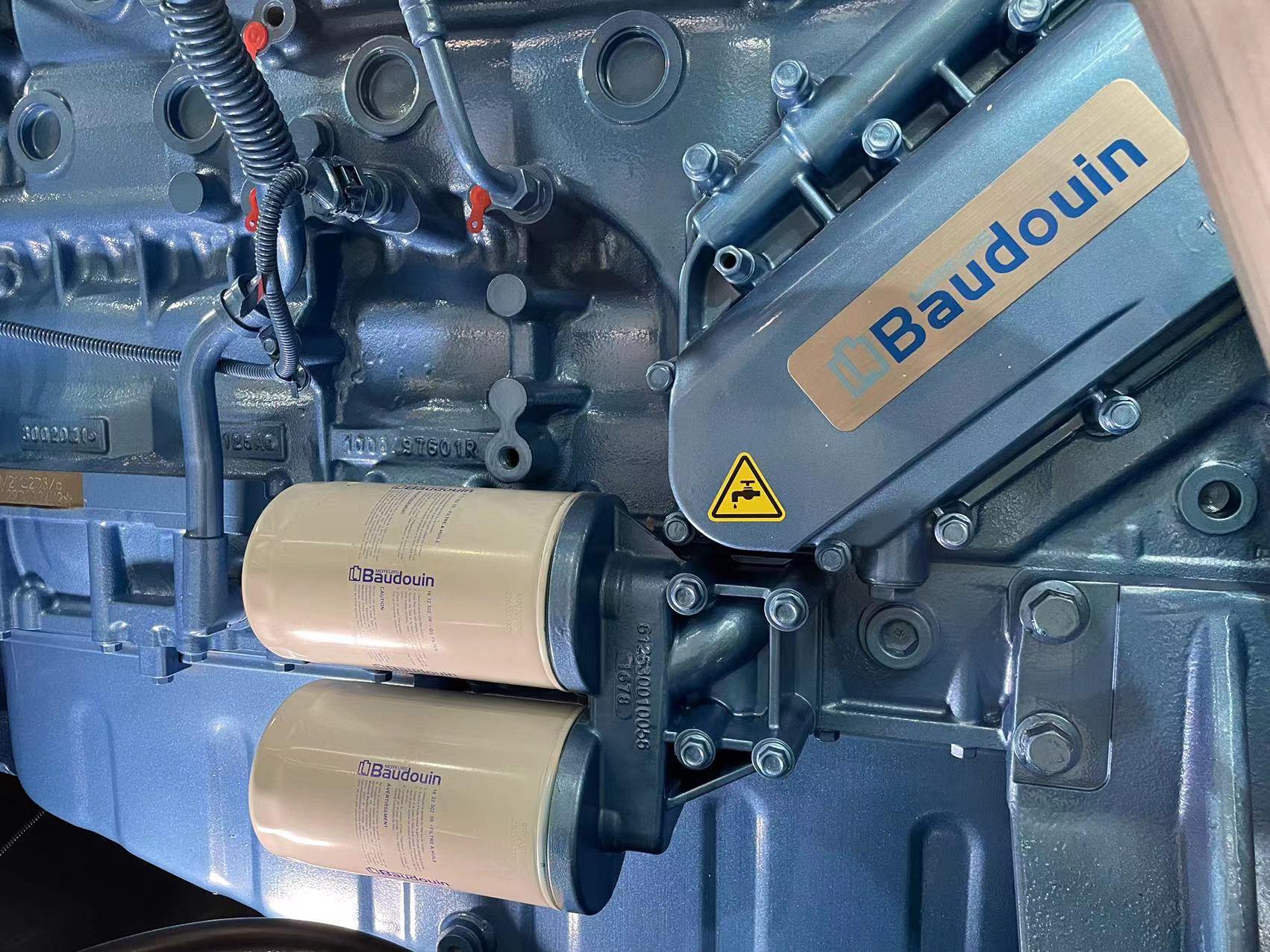

3. Fuel System Checks

Technicians will inspect fuel quality, drain water from the fuel tank (if applicable), and clean or replace fuel filters.

4. Battery Maintenance

A weak or dead battery is one of the top reasons generators fail to start. Battery voltage is checked, terminals cleaned, and charge levels assessed.

5. Coolant System Inspection

Coolant levels, radiator condition, and hoses are inspected. The coolant itself may be topped up or replaced.

6. Air Filter Replacement

Dirty air filters reduce engine performance. These are cleaned or replaced depending on their condition.

7. Load Bank Testing

This simulates full electrical load to ensure the generator can handle real-life demands without issue.

8. Exhaust System Review

Exhaust pipes and mufflers are checked for blockages, cracks, and corrosion that could cause emissions or performance issues.

9. Control Panel Diagnostics

The control system is reviewed for error codes, warning lights, and software updates where applicable.

10. Lubrication of Moving Parts

All moving parts are lubricated to reduce friction and prevent premature wear.

Having a professional carry out these tasks on a scheduled basis ensures your generator stays in top condition for years to come.

In Conclusion: Stay Powered, Stay Prepared

When the lights go out, your generator should be your unwavering line of defence. But without proper care, even the best equipment can let you down. Regular generator maintenance is not just a recommendation — it’s a necessity for long-term performance, safety, and peace of mind.

At National Generator Sales, we don’t just sell generators – we offer complete power solutions. Whether you’re looking to upgrade your current system or invest in a new, reliable generator, we’ll guide you every step of the way.

We’re proud to serve clients across the U.K. with industry-leading technology, tailored installations, and unmatched expertise.

Contact us today to discuss your power requirements — and let’s build a future where you’re always powered, no matter what.

FAQs

How often should a generator be serviced?

Most generators should be serviced at least once a year or after every 100–200 hours of use. Always follow the manufacturer’s guidelines.

Can I maintain my generator myself?

While basic checks (like oil level and visual inspections) can be done yourself, professional servicing is recommended for in-depth maintenance and safety.

What happens if I skip maintenance?

Skipping maintenance can lead to generator failure, reduced lifespan, expensive repairs, and safety hazards.

Does generator maintenance affect warranty?

Yes. Many warranties require proof of regular maintenance to remain valid.

How long does a generator last with regular maintenance?

With proper care, commercial generators can last 20–30 years or longer.

What fuel problems can affect generators?

Fuel contamination, stale diesel, and water ingress are common issues. Regular checks help prevent them.

Do all generators need load bank testing?

Load bank testing is especially recommended for standby generators that don’t run often. It verifies they can perform under real-world conditions.

Why is my generator using more fuel than usual?

Dirty filters, engine issues, or improper load balancing can increase fuel consumption.

How do I choose a maintenance provider?

Look for certified, experienced technicians with good reviews and a clear understanding of your generator brand and model.

Do you offer generator servicing?

At National Generator Sales, we don’t currently offer maintenance services. However, we can recommend trusted partners in your area.

Ready to Power Up?

National Generator Sales is your trusted partner in power generation. We offer cutting-edge generators, tailored installation services, and expert advice to ensure your operations never skip a beat. Whether you’re looking to invest in a new generator or upgrade an existing system, we’re here to help you find the perfect solution. Get in touch to speak with one of our power solution experts today.